Food preservatives. Makeup products. Plastic bags. Advil. What do all of these things have in common? They are all made with a chemical called propylene oxide, a widely produced organic compound used to facilitate several manufacturing processes.

In most cases, propylene oxide is produced by reacting propylene with hydrogen peroxide or hypochlorous acid. However, the hypochlorous acid reaction discharges a toxic chemical into the environment, and the hydrogen peroxide reaction has a dangerous tendency to explode, making both methods of production equally unfavorable.

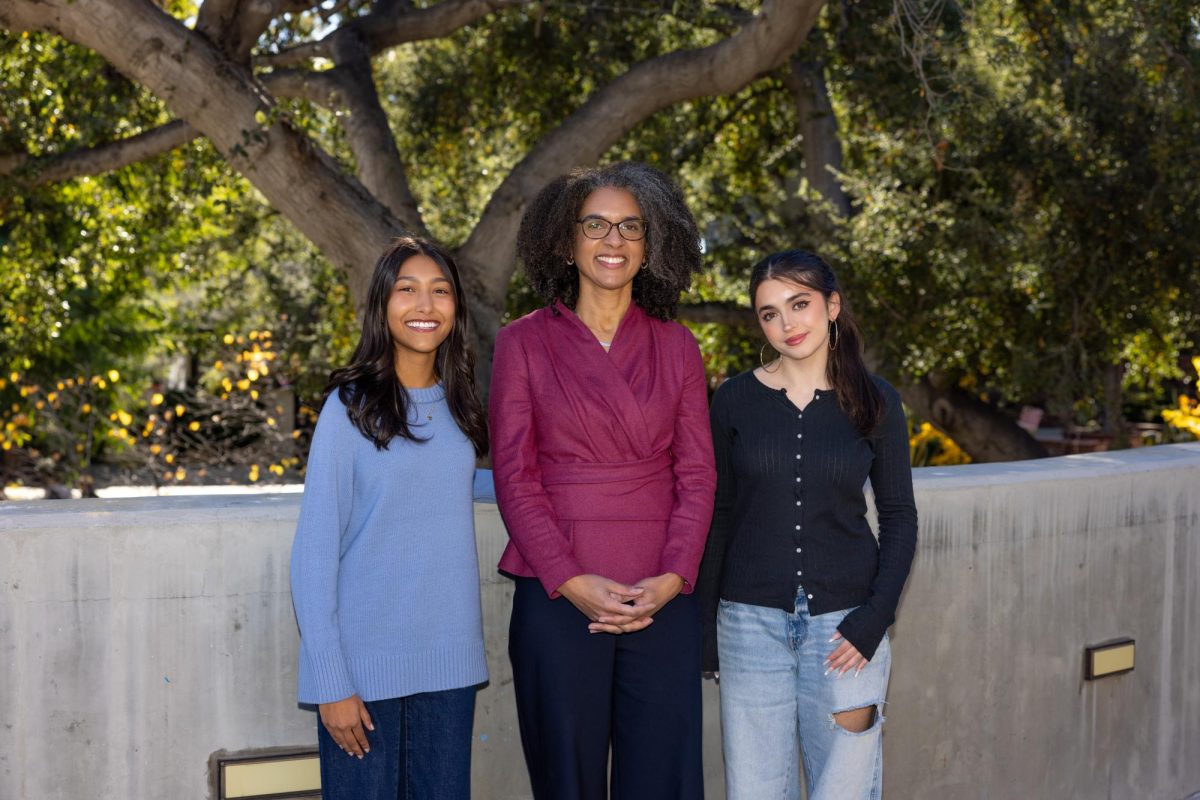

Caltech Professor of Chemical Engineering and Chemistry and William H. Hurt Scholar Karthish Manthiram set out to find a more environmentally friendly way to produce propylene oxide. In an article published in “Science” on Jan. 4, he and his lab concluded that reacting propylene with the oxygen found in a water molecule and adding a catalyst to the reaction functioned as a safer, more effective way to produce the compound. The only byproduct of the reaction was a nontoxic hydrogen gas useful in other manufacturing processes.

Manthiram commented, “The biggest challenge was finding a way to make water the source of the oxygen atoms. Then, on top of that, a suitable catalyst had to be designed.” The researchers eventually settled on a combination of platinum and palladium oxide. The catalyst makes oxygen more reactive with propylene through a transfer of electrons and speeds up the reaction. The oxygen-propylene reaction catalyzed by platinum-palladium oxide not only increases the efficiency of propylene oxide production by 13% and the rate of production by 10% but also does not produce an environmental discharge or have a large carbon footprint.

Upper School science teacher Richard White commented, “We hope that the important work being done by these relatively young scientists can serve as an inspiration to Poly students.